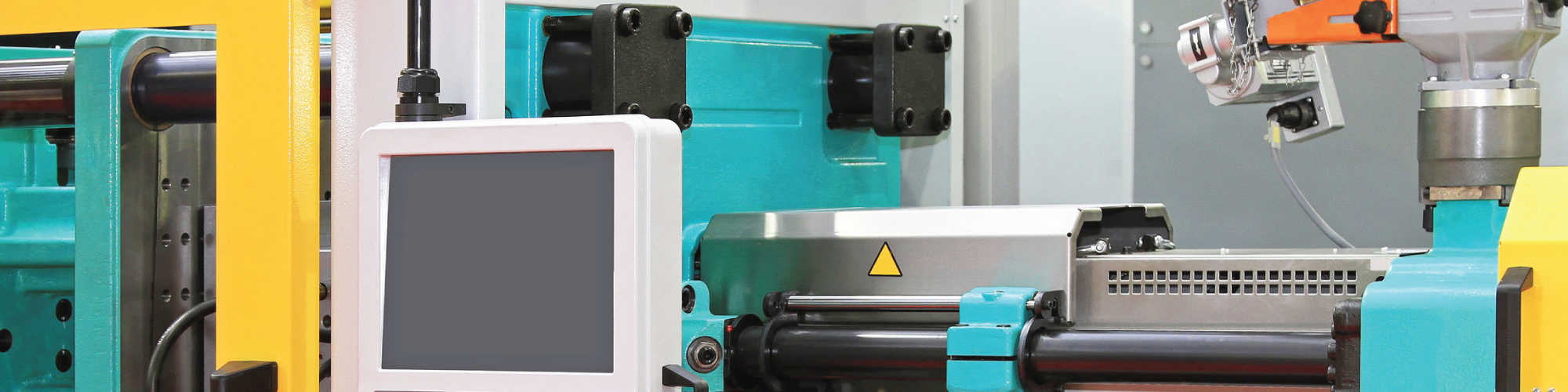

Typical Plastic Injection Molded Parts

Plastic injection molding technology consists of feeding plastic material into a heated barrel. The material is mixed and then led into a mold cavity, where it takes shape and hardens into the final product.

What you might not know is that plastic injection molding has a bevy of advantages and benefits over comparative plastic processing and manufacturing methods. Plastic injection molding is such a precise method that it can fabricate nearly any type of plastic part. There are certain design restrictions, but the molds that are made allow the finished product to be very precise. This makes it a very widely used production method. With such accuracy and precision, plastic injection molding is used in almost everything you touch in some form or another.

The History of Plastic Injection Molding

When you really stop to think about it, it’s hard to imagine a world without plastic. Plastic is used in such a wide variety of products. Its versatility makes it perfect for anything from simple lunch boxes to more complex things.

But before plastic and injection molding were discovered, mankind had to make do with more natural materials, like wood ivory and metal.

The rise of plastic injection molding started with Charles Goodyear’s discovery of vulcanization. After this, various contributions to the development of plastic were made by scientists and inventors through the 19th century, making plastic a common material used to mass produce household items by the mid 20th century.

Plastic Injection Molded Parts in Different Industries

It’s easy to think of things like containers, bottles and other common plastic goods. But plastic injection molded parts are required for most industries nowadays. Examples of industries that need plastic injection molded parts include:

Technology

While things like cellphones, computers, televisions and even USB memory sticks need a lot of parts made with metals, these items always feature some plastic molded parts too. Phone and computer covers, or often times even screens, are made from injection molded plastic.

Medicine

Medicine is a lot like another branch of technology, and so many things doctors use on a daily basis (even in surgical theaters) are made of plastic.

Automotive industry

While the engine, doors and wheels of a car aren’t made of plastic, the interior of most vehicles are filled with plastic molded parts.

Construction

Once again, barely anyone thinks about plastic molded parts used to build, but plastic is used to make things like plumbing pipes and electrical switches, for instance.

Fashion

In the fashion industry, injection molded plastic parts are often used for items such as buttons and buckles. And while polyester material isn’t injection molded, it’s worth mentioning that even a lot of materials used to make garments are made from plastic.

In reality, it’s hard to think of an industry that doesn’t use plastic molded items for some purpose. Even CD’s and DVD’s are made from injection molded plastic. And before CD’s and DVD’s cassettes were made from plastic too!

Benefits of Plastic Injection Molding Parts

When you stop to take a look at the plastic injection molding process, it’s no wonder plastic is such a commonly used material in the 21st century. There are multiple benefits to plastic and the injection molding process that aren’t possible when using a different process or material:- Flexibility: Because there’s such a wide variety of different plastics available, injection molding is a good process to produce products with different qualities regarding durability, resistance to temperatures and hardness.

- Production speed: Plastic injection mold cycle times make it easy to mass produce products and create hundreds of plastic injection molded parts every day.

- Precision: With a good mold, every plastic injection molded part will be an exact duplicate of the previous. Molds can also be designed to create highly detailed parts that can be easily mass produced.

- Cost effectiveness: Compared to other production processes, plastic injection molding is by far the most cost effective for mass producing parts.

Although other materials and production processes will never become redundant, it’s clear to see why plastic has become one of the most commonly used materials in the 21st century.

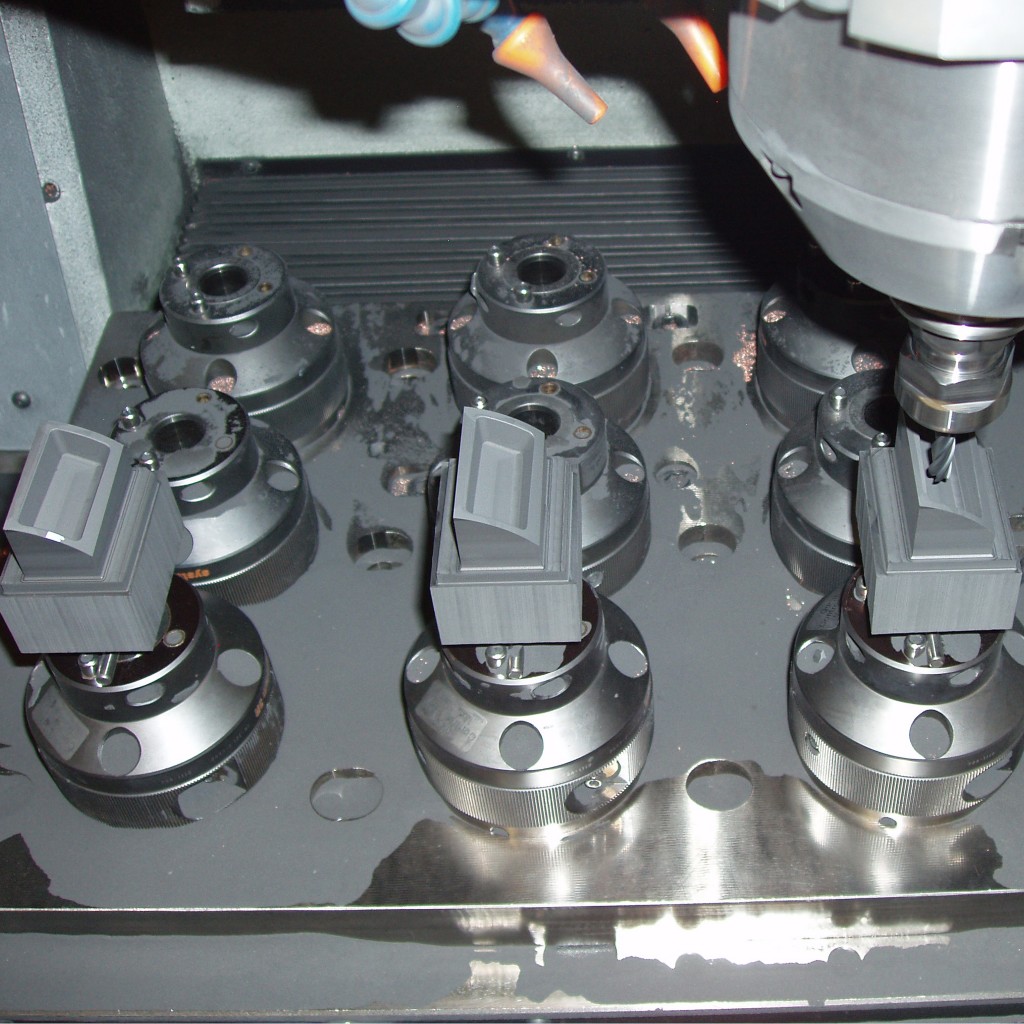

Producing Quality Injection Molded Parts

Plastic injection molding by far outperforms a process like 3D printing for mass producing parts. But even though plastic injection molding may seem easy, it’s not. Producing plastic molded parts requires knowledge about different plastics, their melting points and how the injection molding process works.

A high quality plastic injection mold is also an essential part of molding parts that are free of defects, such as flow lines or surface delamination. Because of this, it’s worth investing in a high quality plastic injection mold.

Too many plastic injection molders try to save on a mold by importing from abroad, but this is rarely worthwhile. When you buy from an American injection mold manufacturer, you can usually count on better quality and mold design. Because your injection mold manufacturer is closer, it’s also easier to arrange for molds to be regularly maintained, so ensuring you get the most out of every mold!

Recent Comments