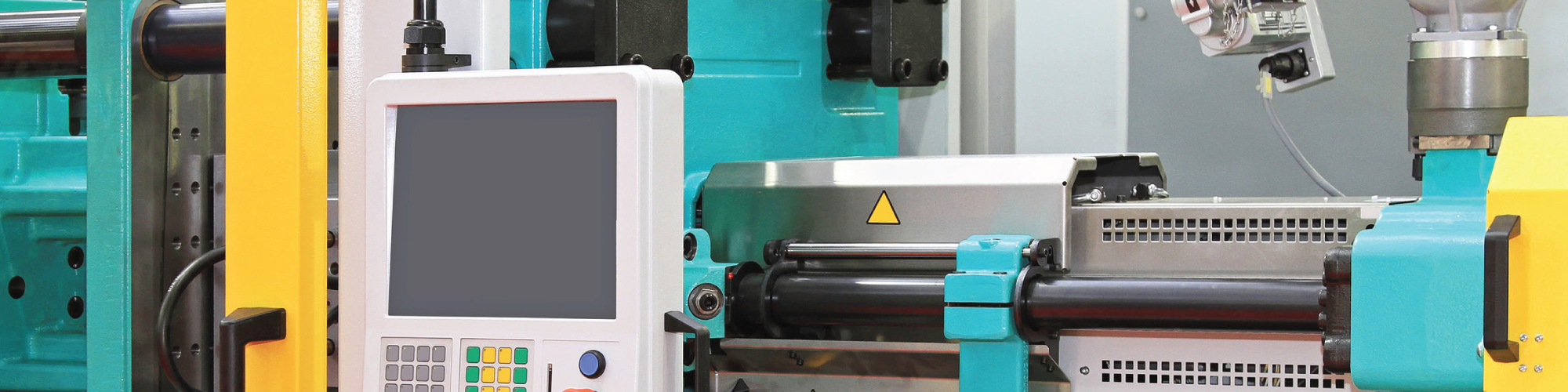

Various Injection Molding Equipment

While most people think of painting, sculpting and carpentry as art forms, few people will look at mass produced plastic goods in the same way. After all, plastic goods are often cheap, and most people only consider something art if it’s exquisite. But while plastic injection molding isn’t necessarily an art form, it’s definitely a process that requires professionals with enough knowledge and skill to get the job done properly. Injection molding isn’t as simple as pouring molten plastics into molds. Many variables can affect the outcome, and mistakes often lead to molding defects.

But qualified professionals who know about using an injection mold isn’t the only thing that you’ll need to mold quality parts. No amount of background in injection molding can compensate for a bad mold. Once you take a moment to consider the process of making a plastic injection mold, you’ll soon start to see the art in plastic injection molding.

Why Quality Injection Molds Are A Valuable Investment

Imagine trying to produce plastic parts without an injection mold? Even if it were possible, the process wouldn’t be very versatile or efficient. This is the case with plastic injection molding alternatives, like 3D printing, where parts can be produced without molding them in a specially-made mold.

The problem with a process like 3D printing, however, is that it’s remarkably slow compared to plastic injection molding, so even though 3D printing is useful in its own right, it’s not a practical process for mass producing plastic goods. At best, 3D printing is good for prototyping goods before you have an injection mold made, or for making a custom-made product that won’t be mass produced. So although some people hope that 3D printing will one day replace plastic injection molding altogether, this isn’t something that will happen in the near future.

With that that in mind, it’s safe to say that plastic injection molds will remain as valuable to the manufacturing industry as tractors are to the modern agricultural industry. Injection molds are what distinguishes the modern manufacturing industry to make large scale production possible.

And when you think about it, your plastic injection molds are what will define your plastic parts. The part will take whatever shape the mold allows, and if your mold is flawless, your part will be too. However, just like a flawless mold can produce flawless parts, a mold with a critical defect will only be able to mold parts with defects.

Why Cheap Molds Aren’t A Good Option

All too often, plastic injection molders will buy the cheapest mold they can find, only to find that it’s defective upon arrival. This is already bad enough in itself, but to make the situation even worse, the defective molds are often imported from overseas, and so sending them back for repairs can take months. When you consider the fact that those molds should be working to earn money for your business, buying a defective mold from abroad can cost tens and thousands of dollars.

But to make a bad situation even worse, mold owners don’t usually send defective molds back to the cheap plastic injection mold manufacturer for fixing. After all, what hope is there to get a mold working by sending it back to a manufacturer that couldn’t produce a working mold in the first place?

Because of this, plastic injection mold owners often look to American injection mold suppliers to fix imported molds that were defective upon arrival. And make no mistake, buying a cheap mold and getting it fixed isn’t more cost effective than getting a proper mold to begin with. On the contrary, this usually ends up being more expensive than buying a quality American-made injection mold from the start.

Injection Molding Equipment: Maintenance vs Repairs

Getting your injection molding equipment made by a mold maker that has a high quality standard is definitely the first step in effortlessly producing quality plastic parts on a consistent basis. But to keep everything running smoothly, mold maintenance will be necessary, and (in some cases) repairs too.

A mold maintenance schedule will help prolong the lifetime of your molds. And considering how expensive plastic injection molds tend to be, this is a worthwhile investment. The extra life and service you can get from a mold that’s well-maintained by far makes up for the cost of maintenance.

Don’t be too quick to believe financial advisors who suggest that cutting on maintenance can save money. All too often, financial advisors are trying to make immediate savings for a business by neglecting to consider what’s more sustainable in the long-run. This is especially true when the advisors are pressured into setting up reports that show where they were able to save a business money.

As injection mold professionals, we can confidently say that well-maintained molds last longer, perform more reliably and save large amounts in expensive repairs.

Knoxville Injection Mold Suppliers

Whether you want a brand new mold expertly designed and made from scratch, or repair an existing mold, Quality Mold Shop can help you. When it comes to plastic injection molds, there’s little we can’t do. From reverse-engineering a mold to make an exact duplicate, to fixing a defective mold you bought from another supplier. Our team will also gladly service any mold bought from any supplier, including imported molds.

Recent Comments